Whether you own or rent a commercial space, you must understand the potentially fatal risks of arc flash and how to safely handle it. Keep reading to know all the information you require.

So, what is arc flash?

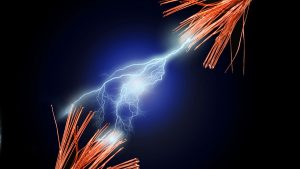

An electrical explosion or discharge known as an arc flash (also known as a flashover) happens when electric current passes from a conductor to a ground or through the air between conductors.

When a wire comes into contact with an earthed system, for instance. This leads to an explosive release of energy in the form of light, pressure, heat, sound, and shrapnel.

Unmasking the Phenomenon: What is Arc Flash?

An arc flash is typically caused by an improperly functioning piece of equipment, such as an electrical wire. Also, it can be the consequence of someone working on machinery, which allows the electricity to escape from its usual path.

Electricity always follows the least resistance path. Because of this, arc flashes won’t always occur once something is broken or a different route becomes accessible. Rather, the energy will proceed down its planned course until a less-resisting alternative becomes available.

Here are a few scenarios that can create a less resistance path and an arc flash:

- Dust

- Tools dropped onto a wire

- Accidental Touching

- Condensation

- Material Failure

- Corrosion

- Improper Installation

The Science Behind Arc Flash: Temperature and Energy

An arc flash temperature can reach up to 20,000 °C, which is around four times hotter than the sun’s surface.

Temperatures that high can easily melt metal, burn the skin, cause eyesight and lung damage.

The temperature generated in an arc flash depends on the amount of heat energy released during an electric arc explosion.

Arc flash energy depends on the flash length and the short-circuit current available, and its potential hazards are related to the distance from the flash origins.

Perilous Consequences: Arc Flash Dangers and Injuries

Electrical arc flash can result in blast injuries, eye injuries, hearing loss, lung damage, and serious burns. Arc flashes are uncommon, but when they do occur, the effects on employees and the company may be severe. Equipment protection and life preservation can both be achieved by maintaining a high level of awareness.

Long-term health implications for individuals exposed to arc flash incidents include post-traumatic stress and even depression or anxiety.

Some sort of post-traumatic response is completely normal after an arc flash injury, but sometimes it starts having a negative impact on a person’s everyday life and professional relationships. In these cases, it is important to receive proper treatment, because disorders may become more severe.

Depression is also a typical reaction to traumatic or stressful experiences, thus these two conditions can occur at the same time.

Root Causes of Arc Flash Events

So, what causes arc flash? An arc flash can result from equipment failure and human error, or inadequate maintenance and improper equipment installation. Preventive measures to mitigate the risk of arc flash events include regular inspections and maintenance to recognize and fix insulation issues before they become dangerous. Another crucial step is that only qualified employees are allowed to handle and operate electrical equipment because incorrect use can damage insulation and cause an arc flash.

Arc Flash Awareness and Training: A Vital Necessity

Arc flash training is essential for workers in high-risk environments, such as electrical engineers, electricians, employees working near electrical equipment, electrical supervisors, etc. Because human error plays a significant role in injury or death from arc flash.

The key components covered in arc flash training programs are the following:

- Primary hazards of electricity

- Arc flash hazard

- Shock hazard

- What is an electric arc

- Measuring arc flash

- Legislation/safety policy

- Arc flash risk assessment

- How the process works

The importance of arc flash warning label and arc flash protective equipment can not be overestimated. The labels contain important details concerning potential hazards, including nominal system voltage, incident energy, flash protection boundary, necessary PPE, and other relevant safety data. An arc flash protective equipment is designed to withstand and minimize injuries that may be caused by an arc flash.

Case Studies: Lessons from Arc Flash Accidents

Every arc flash training should include studying and analyzing past arc flash accidents and their underlying causes to learn from others’ mistakes. Learning about each incident helps reinforce why adherence to safety protocols is vital and prevents recurrence.

Some notable cases include:

- A maintenance electrician neglected to follow lockout requirements and improperly worked on a live 480V panel, as a result, he got severe burns over 65% of his body.

- After accidentally dropping a power tool onto a 7.2kV bus while doing a hot panel check, a utility worker was hospitalized with third-degree burns; improper protection equipment worsened injuries.

- When cleaning a live MCC bucket without wearing voltage-rated gloves, an apprentice electrician lost three fingers and got facial burns.

Every seemingly insignificant break of safety rules could have disastrous consequences. Electrical safety training, PPE, and protocols exist to protect employees from these avoidable tragedies. Shortcuts don’t exist in electrical safety.